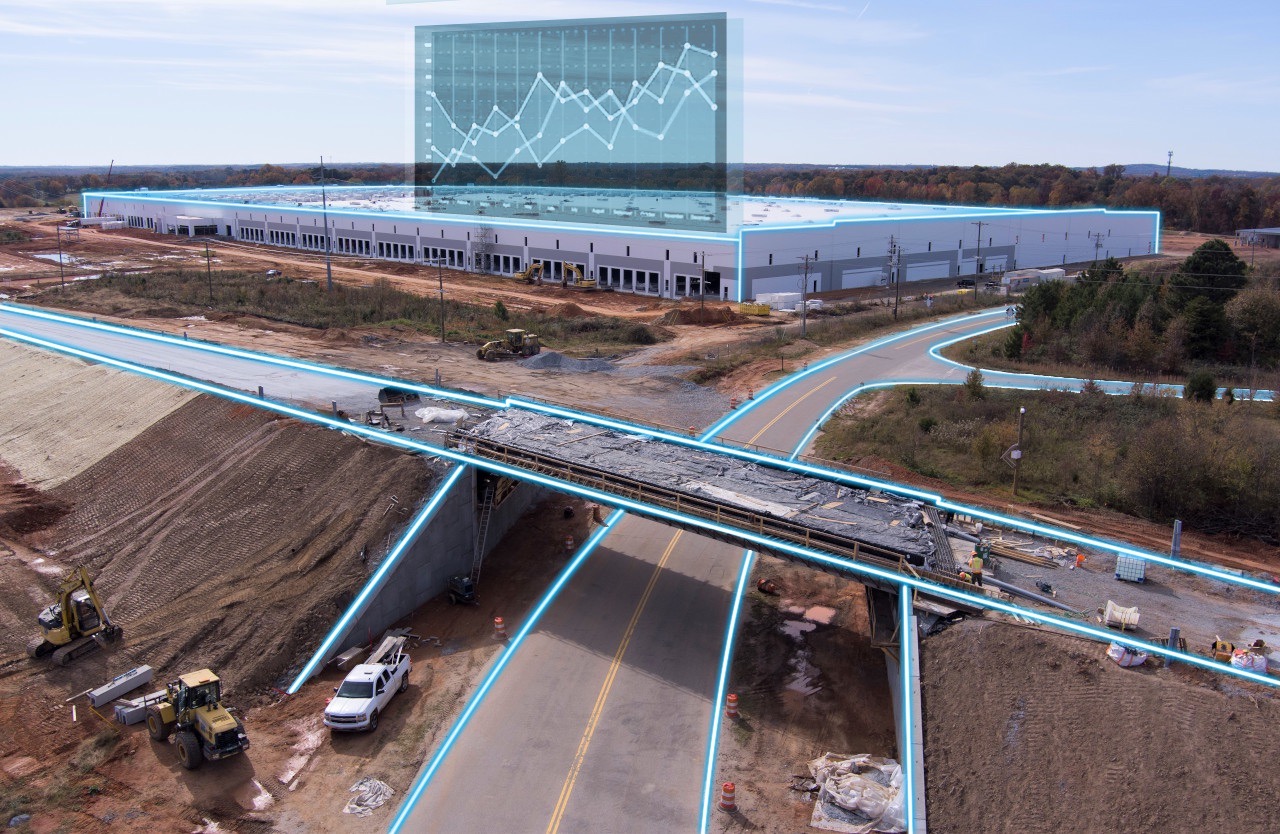

Construction

Leading VDC & BIM Consulting Services

Unlock the potential of your projects with VIATechnik's BIM and VDC consulting services, designed to streamline execution, reduce risk, and optimize cost-effectiveness.

Proven & Holistic Expertise

Dive into the future of construction with our industry-leading VDC and BIM consulting services. With experience from thousands of projects, we guide clients through technology transitions to drive efficiency and competitive advantage.

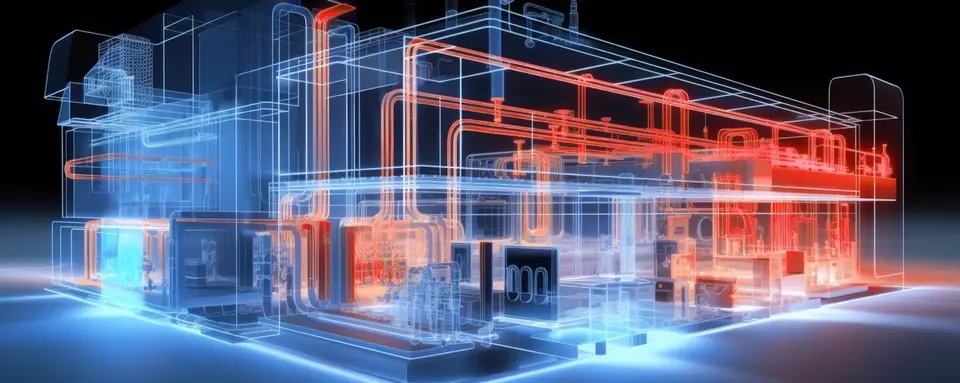

Seamless Integration of BIM & VDC

We specialize in the seamless integration of BIM and VDC methodologies. Our consulting services bring together the power of these transformative technologies, allowing for enhanced collaboration, accurate project visualization, and streamlined construction processes.

By integrating BIM and VDC, we enable our clients to unlock the full potential of their projects and achieve exceptional results.

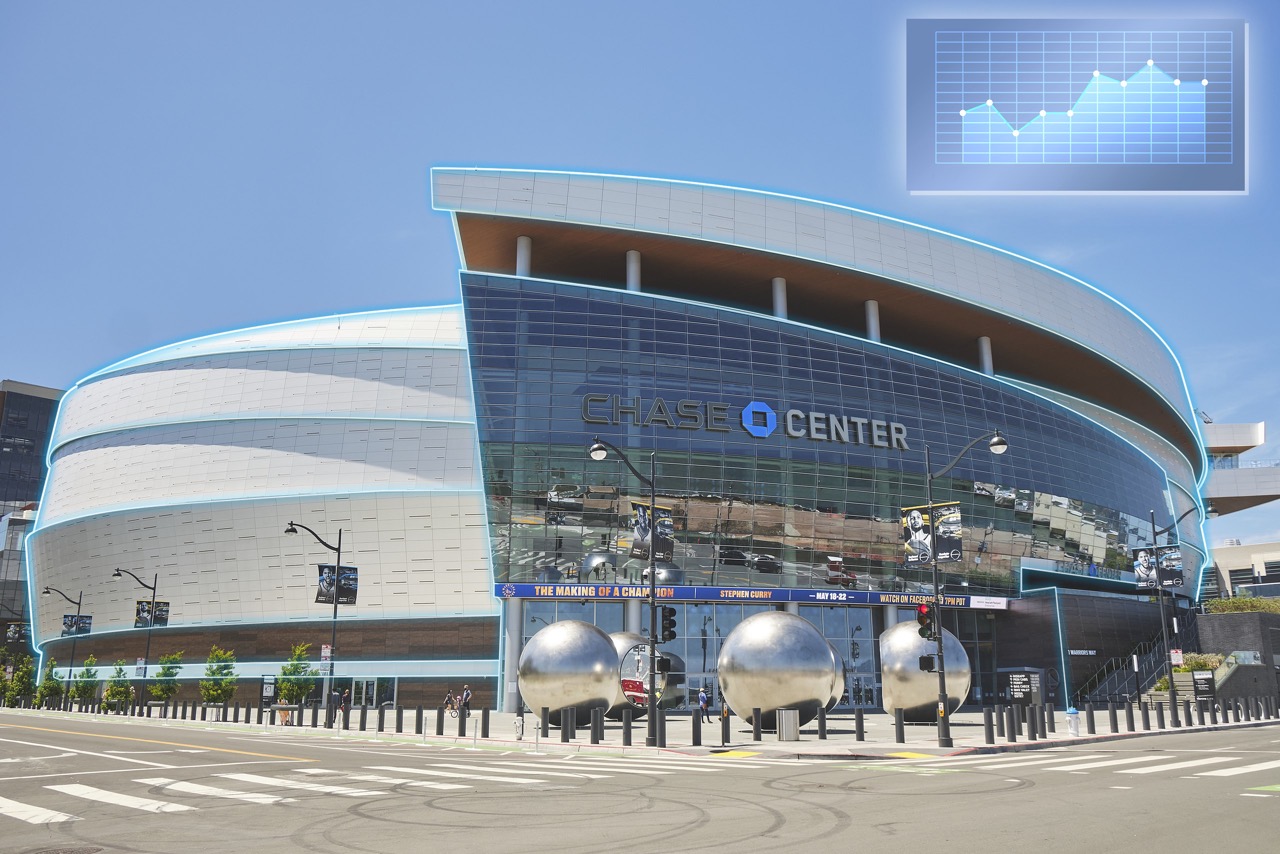

Harnessing Technologies

At VIATechnik, we are committed to harnessing technologies in our BIM and VDC consulting services. We stay at the forefront of industry advancements, utilizing state-of-the-art project management tools, advanced BIM automation techniques, and innovative VDC applications.

By integrating these technologies seamlessly into projects, we empower our clients with the tools they need to enhance efficiency, mitigate risks, and optimize project outcomes.

Cultivating Industry Leaders

In addition to offering strategic consulting, VIATechnik takes a proactive role in fostering the next generation of industry leaders. We provide our clients with comprehensive training in BIM and VDC methodologies, creating an ecosystem of learning and growth that extends beyond the duration of our involvement.

Our training programs, including leading Revit training, empower your teams to develop best-in-class capabilities and utilize these complex technologies effectively and efficiently in the short and long term.

Prioritizing Client Vision

We believe that no two projects are identical, and our consulting approach reflects this belief. That’s why we prioritize the unique vision and objectives of each and every client we work with.

Rather than employing a blanket approach, we tailor our BIM and VDC strategies to resonate with your project’s unique requirements and objectives. Our team works closely with stakeholders to understand the nuances of their vision, ensuring our technological strategies align seamlessly with their overarching goals.

The VIATechnik Difference

At VIATechnik, what sets us apart is our steadfast commitment to our core values. With every engagement, we embody unmatched expertise, provide tailored solutions, and tirelessly pursue opportunities for innovation to drive exceptional project outcomes.

Collaboration

Facilitating open communication and collaboration for better-informed decisions.

Integration

Ensuring seamless integration of design, construction, and operation data throughout a project’s lifecycle.

Innovation

Innovation is at the core of VIATechnik, driving transformative solutions.

BIM Services

Discover the industry’s best VDC and BIM consulting services.

Contact Us